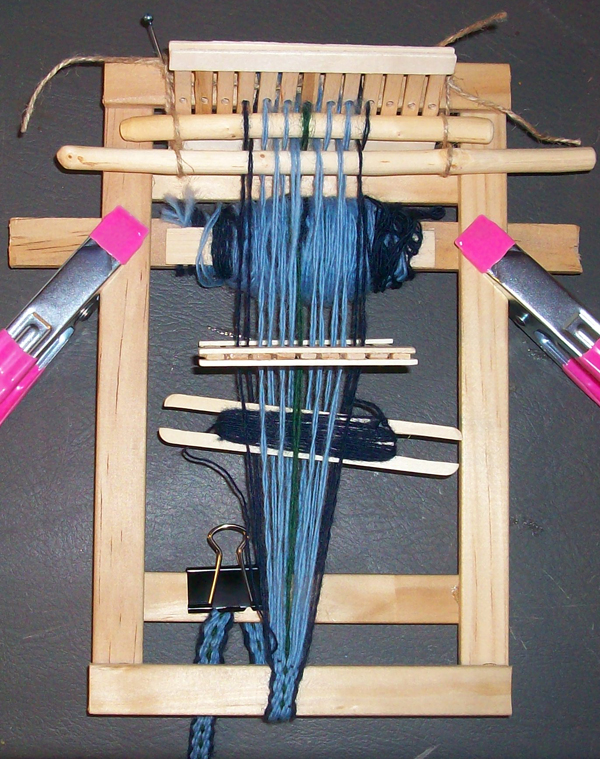

The Loom That Laura Made

The yarn here is handspun, and then plied, so it is a fine spun thread that has been plied into a two ply yarn.

I am using a single ply, thinner, weft thread, and this pulls it to give it a somewhat scalloped appearance on the sides of the finished ribbon.

This loom was made of thin wall trim, glued together with shoe goo. I made the shuttle and heddles also. More shoe goo.

The warp winds around another wood piece on the back, and I use the two clamps to anchor that wood piece so it won’t unwind.

I also peeled and scraped two pieces of elm branch, to use as raddles at the top. They separate the threads (use the heddle – drop it and insert one raddle, then raise it and insert the other raddle), so they don’t get tangled at the top of the loom. This is how I used it the first time.

Shown here is a SECOND heddle, right at the top of the loom, and I used that on this weaving, to see if it was easier to keep the warp threads from tangling as they unwound from the wood piece on the back. It did help – I didn’t use the raddles at first, but put them in later for this picture to show what they were supposed to be doing. Use of the second heddle there is not needed, it is just an optional thing. Once you start weaving, it doesn’t do anything to help things stay neater if the raddles are in use.

When warping the loom, the second heddle in the back can be moved out to the ends of the warp threads to keep them neat and even as you roll the warp onto the back stick. I kept that heddle just in front of the threads I was winding onto the stick, and it kept them neat and even as they went on.

I’m only using this for shoelaces. It is really too small for any other kind of compressed warp weaving, the heddles that fit it are just too narrow. I could use it for narrow balanced weavings that turn out the full width of the heddle, but it would still be mighty small stuff!

You can see the finished lace, and it is pulled down and wrapped around the back brace on the loom, and held there by a binder clip.

To advance the warp, I remove the binder clip, take off the two pink clips, and then unroll the warp stick. I then refasten the pink clips, and pull on the finished weaving to pull the unrolled warp thread up and over, through the heddle and raddles (again, only one or the other is really required at this point). I pull it very tight and re-clip the finished weaving to the back brace. All the rest of the finished lacing dangles off in a pile.

This loom is pretty tiny, and the working space (space between the obstacles at the top, and the frame at the bottom) where you can actually WEAVE, is very short. I have to advance the warp about every 4″. I think this is about as small as I’d ever want to make a loom for making ribbon or bands, or shoelaces.

People do use smaller looms – pin looms, tiny tapestry looms, H looms, and other little bitty things. They are used for small weavings, pieced projects, etc.

This little loom holds up to a 15 dent heddle – that means 15 holes, and 14 slots, for 29 threads total. If using larger yarn it makes a fairly wide piece, and the warp is not compressed. Once you go to band weaving with a compressed warp though, it narrows down considerably, and will only make half that width or narrower, depending on thread weight (the narrower the thread, the narrower the finished piece).

Is it fun? It is faster than I thought it could be – feels faster, anyway. The warping is tedious and awkward. The advancement of the warp is tiresome. The weaving itself is boring, as weaving tends to be. But it is a calm and simple thing to do when I’m tired, or when I’m occupied with something else and just need to keep my hands busy. I don’t really binge Netflix, I’m not the type anymore, but I do spin or weave in the evenings when we watch a movie, and sometimes during the day when I have to sit down.

I’ll be making another of these, much wider. I want to do wider pieces of compressed warp weavings, with band style straight weave and complex weave designs. I have more homemade heddles that have more than one row of holes in them, to vary the weave type.

UPDATE: I did make another wider loom to make wider weavings on, and when I made this first loom I had also made a beveled shuttle. It took several days of sanding and shaping (I only had hand tools to do it). It was pretty hard to do, and I had no motivation to do another one, especially the larger one I really needed. But I had a 4 inch one (Inkle style), when I discovered how to make a simple shuttle from popsicle sticks. I used the stick shuttle for several sets of laces, and found it to be functional, but sometimes awkward due to having to keep track of two ends as I worked it through the warps.

Today, three weeks after this initial post, I tried the beveled shuttle. It is FAR easier to use, it just slides through without hanging up. I’m really glad I learned to make the popsicle stick shuttle, but I’m much happier using the beveled shuttle.

Warp Speed

Weaving, that is. Star Trek never had this.

I don’t have pictures yet. Sorry. But I need to write anyway.

I have a SampleIt Loom. Have had for a few years now. I got it soon after I started spinning. If you spin, you have to USE the yarn you make, or the thread you make. But then, you also have to make ENOUGH thread or yarn.

Problem was, I didn’t have enough of any one thing to really DO anything with on the loom, and warping the loom requires space that I did not have. Still don’t. So my loom sits in the corner, lonely and abandoned looking, gathering dust. Too costly to let it do that forever, I WILL use it. But I need a project that I have enough yarn for first.

Stumbled on Band Weaving. Was not impressed. Then I was. It is quite lovely in many patterns. They used to call it Ribbon Weaving, and sometimes Tape Weaving. Look it up, it is easier than me trying to explain and you getting it all wrong.

Shoelaces. You can make shoelaces with this. Decorative ones. In any color you want, provided you can find the thread. I started with crochet thread, bedspread weight cotton. Works good.

It took WEEKS to get from “I want to do THIS” to actually threading a heddle.

First I had to make a loom. I did. A modification of the Beka 4″ wide loom, mine is wider, and shorter. Just 9″ by 12″. Works much the same, but has a design change on the warp board on the back to make it simpler for me to make.

Then I made an even smaller loom, just a 6X9″ frame. I tied on two raddles, and added a 3/4″ by 1/4″ board that is about 8″ long to wind the warp onto. Tied that on, strung the heddle, and made pink and yellow shoelaces. The colors I HAD that I didn’t mind using on a practice product. I now have two 30″ long striped shoelaces that someone in my family will find in their mailbox sometime around Christmas this year. 25 threads wide, ends up about 1/2″ in finished width.

Next are Kevin’s bootlaces. Navy, Light Blue, and Dark Green. These are about 3/8 of an inch wide. They are wool. Handspun wool. It is what I have on hand. I started these on the same tiny loom, but used some clamps instead of string, to make it faster to advance the warp. The loom suddenly went from simple looking to trashy – the clamps are large, with pink handles and grips.

The thing is, weaving by hand is SLOW. And this is a TINY loom. Even the larger one is SMALL. Weaving ribbon is pretty fast as far as passing the shuttle is concerned. The time is lost in advancing the warp .

Warp thread is the long thread that you put through the heddle (look it up). It runs from the back of the loom to the front, and however many warp threads you put on determines in part the width of the end product.

The threads that go back and forth in the shuttle, to form the rows from bottom to top are the Weft. So you weave the weft into the warp, again and again, until you run out of room. Then you advance the warp – you unroll more thread to use at the top, and you roll up (or just reanchor) the finished weaving at the bottom.

There are all sorts of ways that looms handle this one basic function. Some are easy, and some are hard. Some are simple, but take time. If you make a loom by hand, this is one area where you often have to compromise, and accept a more difficult or time consuming method, in order to simplify the pieces and assembly of the loom.

I’m faster now at advancing the warp than on the first set of shoestrings. With those, I wove about 3-4 minutes, and then spent 2-3 minutes advancing the warp. Now it takes less than a minute to advance the warp, but I’m also weaving wool, which is a bit slower since it likes to cling to itself and does not slip easily when the heddle is raised or lowered. It seems to be taking longer to weave this set of laces, even though I’ve gained so much speed on the warp advance.

Band Weaving is a great place to start, because it teaches you patterns in Straight Weave. Straight weave is just back and forth, every other thread, alternating row to row. So if you have a hole and slot heddle you just lift for one row, and drop for the next row. There are literally hundreds of patterns you can create with Straight Weave, just by varying the colors.

With Band Weaving, it is a Compressed Warp style weaving, so all the warp threads get pushed together tight, and you don’t even see the weft threads. It makes it so you only have to worry about the colors on the Warp, in order to work out a pattern. It can be simpler to start out than many other kinds of weaving.

Kevin is weaving on a Peg Loom, and it is Compressed Weft. So the back and forth threads compact down, and you don’t see the warp threads that hold them together. This simplifies the process for him, he only has to worry about getting things right one direction, not two.

There are other things I want to do. But I have to work out how to make the loom do them. There are problems with small looms that cause aggravation for weavers worldwide, and it makes it difficult to produce even work. Wider and longer finished work compounds those problems, and it gets really awkward to first warp the loom, and then keep the warp from getting all tangled or having uneven tension. I assume there may be solutions. But I cannot find them.

Meanwhile, I CAN make small ribbons. And they make really cool decorative shoelaces.

I am either really crafty creative, or I am really pathetic.